Chongqing Lifan automobile

Model: CA10 MPV

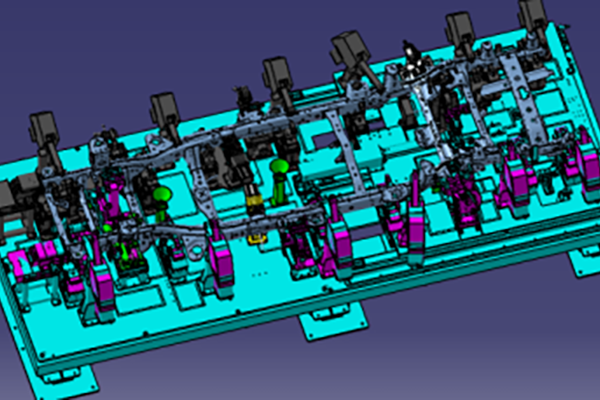

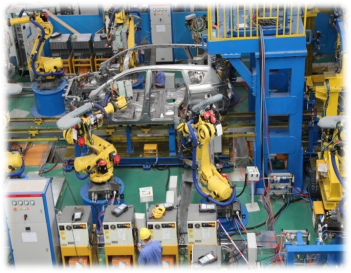

Project content: it is divided into main welding line, side wall line, rear wall line, floor line, front wall line, top cover line, door line and EMS sling conveying system. The body welding line can meet the production of platform series body. There are 34 robots in the overall project, 15 stations in the main welding line and 14 robots, all of which adopt robot automatic welding, 4 robots for floor line body and 16 robots for side line body. The main line is transported in the form of trolley reciprocating, and the qualified rate of the whole vehicle reaches 91-94%, which is highly recognized by customers.

Production program: 32jph development time: 2015 ~ 2016

Related products

|

|

|